Why fashion is the gateway to 3D printing for the masses

As someone who doesn’t have an engineering or design background, I continue to be intrigued by all the ways this industry impacts me every day, starting with my car, the device used to perform my knee surgery, and now one of my greatest loves: clothes.

3D printing is revolutionizing many industries; most people immediately think of the manufacturing and medical industries, amongst others. The fashion industry, however, is usually not at the top of that list. As a $1.2 trillion global industry and with $250 billion spent annually on fashion in the US, 3D printing may have the largest impact on the masses via the fashion industry. Think about it, everyone wakes up, and everyone puts on some form of clothing. But the way that works and how the fashion industry serves the masses is likely to change thanks to 3D printing.

Think of the day when you’re no longer scrambling to find the perfect interview outfit because you can print the perfect blazer to wear to the interview, the same way you print your resume. For consumers, this makes buying clothes easier than ever. It further eliminates the need for planning ahead, ordering multiple sizes in case one doesn’t fit, and having to ship back returns. The future of adding an item to your wardrobe is as simple as receiving a design file in your email inbox and printing your exact size and color in a matter of hours from the comfort of your own home.

Danit Peleg is leading the way for this type of at-home fashion experience. In 2015, although her professors warned against it, Danit set out to create a five-look collection 3D printed from the comfort of her own home. She had only nine months to complete the project, and failure wasn’t an option, as her graduation from Israeli’s top design school, Shenkar, depended on it. Finding the right material was her biggest challenge–it needed to be comfortable, wearable, and thus flexible while still being sturdy. Danit landed on Filaflex which she threaded into an at-home printer to create small textiles that fit together much like a puzzle. It took 2,000 hours to complete these five looks which included 3D printed dresses and skirts and even a pair of modern stilettos.

As you can imagine, this was just the start for Danit. She’s pioneering wearable, 3D printed fashion for consumer benefit. Since Danit’s collection in 2015, she’s produced a new collection three times faster than her original collection, released her first consumer 3D printed line of jackets, launched a customization and personalization platform on her website allowing consumers to order 3D printed garments, and now offers virtual 3D printing fashion workshops.

So far we’ve mostly talked about the consumer benefit to 3D printed fashion, but manufacturers and retailers can reap the benefits as well. Manufacturers are able to greatly reduce waste by having little to no inventory on hand and reduce or even eliminate shipping costs.

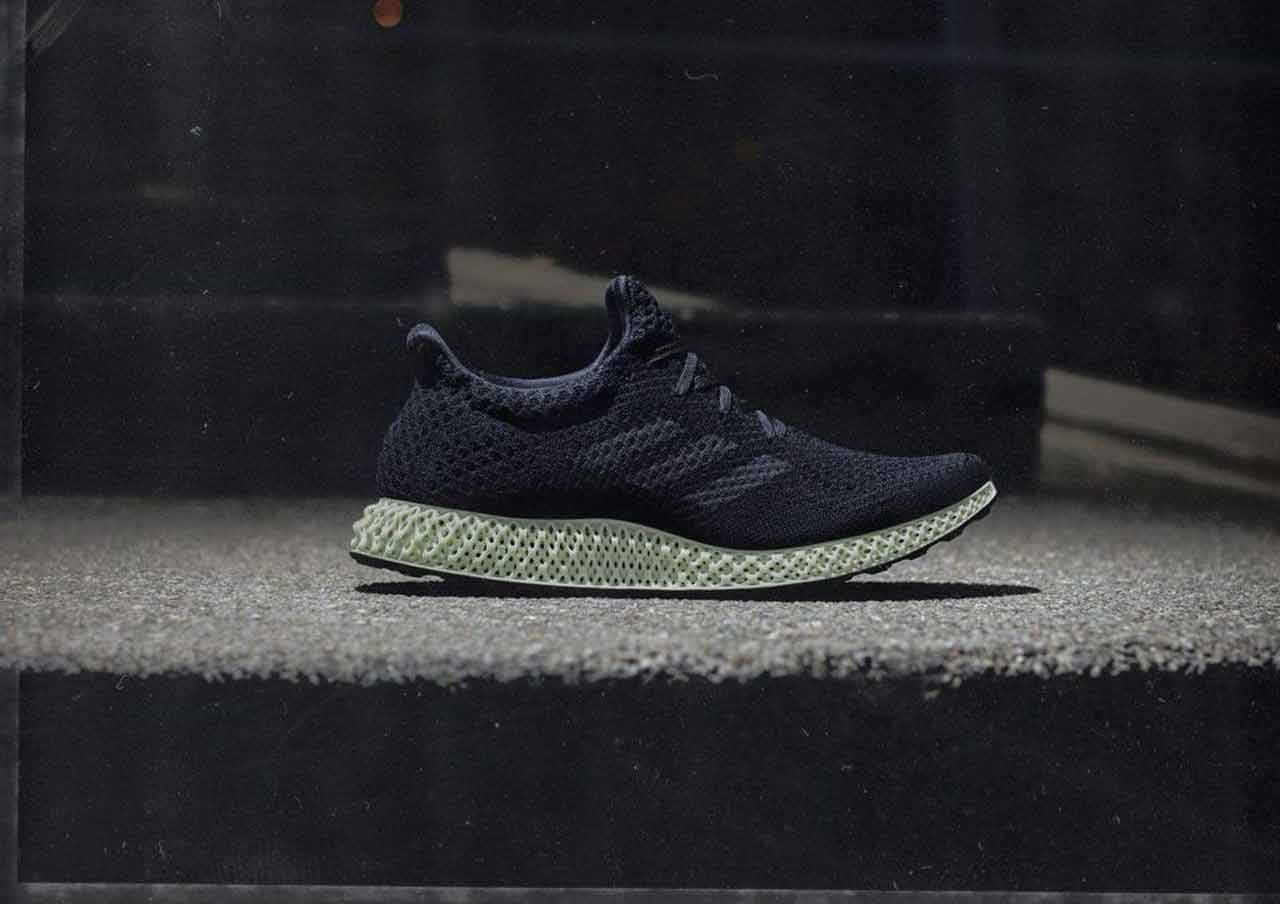

Let’s take Adidas, for example, who has plans to scale their use of 3D printing technology for their footwear lines beyond just prototyping and instead for mass production. Why you may ask? This new technology shortens the product life cycle time and creates an on-demand model, reducing excess inventory risks for Adidas. For their new Futurecraft 4D shoes they were able to cut production time by 5-7 months and it was immediately cost-effective when they quickly sold 100,000 pairs at time of release.

So what does the future with 3D printing look like for Adidas? The next time you walk into an Adidas store to buy a pair of shoes, instead of picking out a pair you like, trying them on, and hoping they have your color choice and size in stock, your foot will be scanned and within minutes a custom shoe personalized for you will be sent to the printer to be 3D printed. And maybe the best part yet? This won’t cost you an arm and a leg because they will be able to cut costs in so many other ways to make this cost-effective for both parties.

Whether we like it or not, our shopping experience is about to change thanks to 3D printing. We may walk into a store and be offered customization with scanning or perhaps we decide to print an entirely new wardrobe from the couch, but waking up and putting on clothes may start to look a bit different in the coming years. As a lover of fashion, I’m excited to see where this goes.