Advanced SOLIDWORKS surface modeling practice exercises

Whether you’re designing aesthetically pleasing consumer products, modeling curvature continuous Class A surfaces, or creating decorative goods like jewelry and light fixtures, you can utilize SOLIDWORKS surface features to construct complex geometries that are otherwise impossible to create.

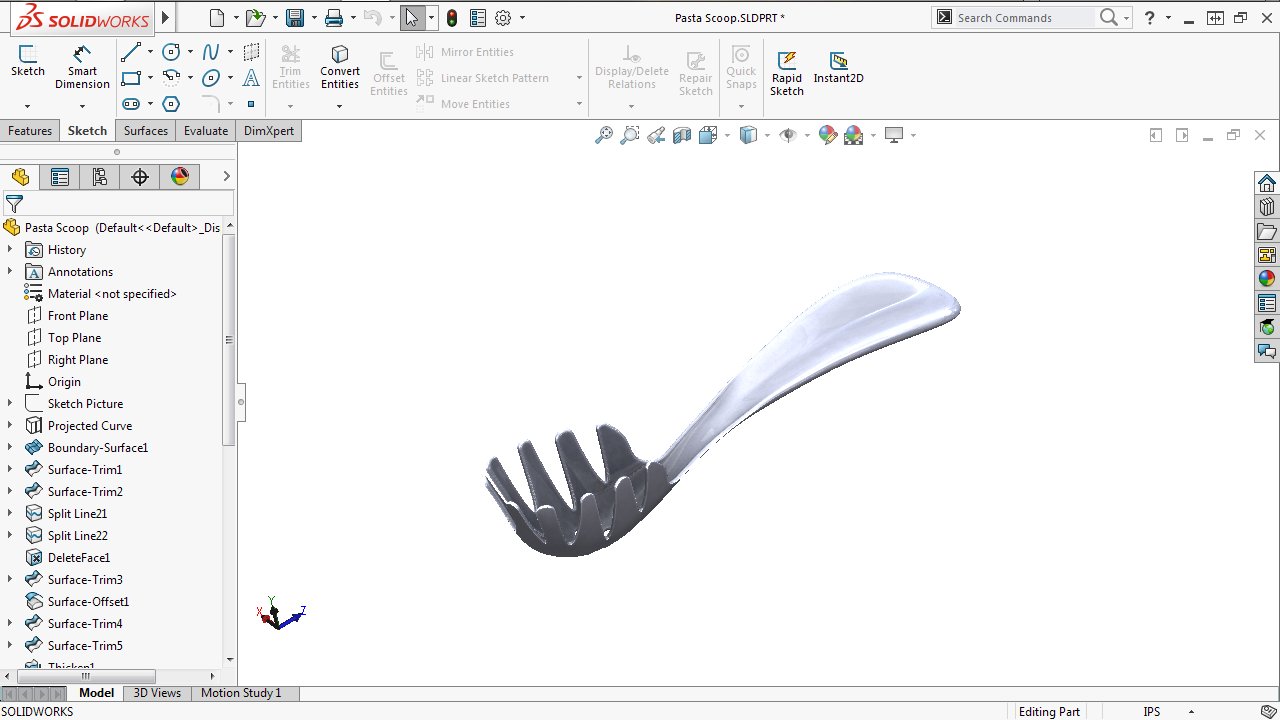

In these three case studies, we’ll show you how to take your existing surfacing knowledge and apply it to create a finished product. You’ll know how to reverse engineer products from existing images or sketches, build models one face at a time, utilize surface modeling to get the geometry you want, and work with both solid and surface bodies to create the finished product.

Reverse engineering a 3D model using an image

Creating curvature continuous transitions

When designing consumer products, it’s useful to blend multiple surfaces together to create curvature continuous transitions. Learn how to create a variety of surface features that will be combined into a smooth and refined final product. By the end of this case study, you’ll have modeled a detergent bottle using a sketch representing the outer shape of the bottle and handle and be able to apply this technique to any other consumer product you may need to design in the future.

Creating aesthetically pleasing products

In the last of this series of case studies, you’ll model a candle holder from a rough sketch outlining the product. You’ll be able to apply solid and surfacing features to create aesthetically pleasing products that stand out from others in the market. This case study demonstrates some of the decorative modeling techniques commonly used for jewelry, light fixtures, furniture, and casting. To create the model, you’ll use a combination of solid and surface features, such as revolved boss, swept boss, boundary surface, and freeform surface.

All three of these case studies teach you a variety of surfacing techniques applicable across a number of disciplines. These techniques will save you time and energy when modeling, improve your 3D modeling techniques, and increase your work productivity.

Earn SolidProfessor Technical Certificates by completing all of the lessons in these case study courses and scoring an 80% or higher on the course review tests.